Do I Need a Line Wrench

Do I need a line wrench? That was a question I needed an answer to many years ago. I was just starting out working on my car. I needed to work on my brakes and I needed to work on the brake lines. It seemed so simple. The nut used on the brake line did not appear to be any different than hex head bolt. Why can’t I use a combination wrench on it? That way I can keep my money in my pocket and not spend it on a specialty tool. I soon found out that I needed that specialty tool.

Why this kind of wrench?

Line wrenches are used on brake lines, fuel lines and power steering and bicycle cables. But first what’s different about a line wrench? A line wrench can be called by many names. It can be called a flare nut wrench, a brake wrench, tube wrench, flare spanner, flare nut spanner, brake spanner, and a crow’s-foot spanner. All of these names for the same type of wrench.

They look different

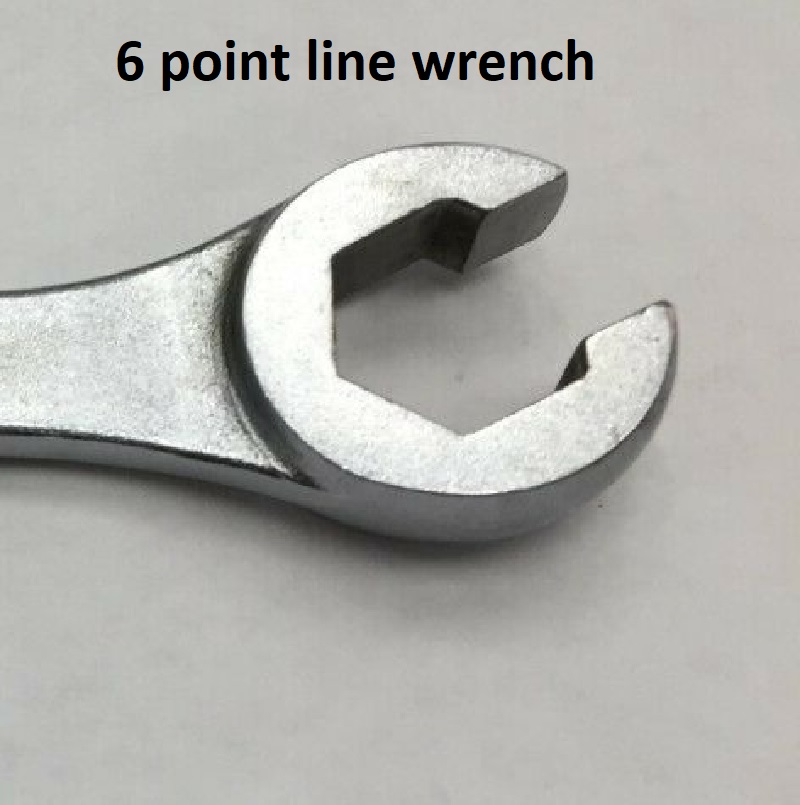

The line wrench is different, it has an opening in what would be the box end(see photo below) of the wrench. This opening allows you to slip it past the brake line or fuel line without having to remove it. It can come in two types. A six-point and twelve-point version. The design can have a small angle(an offset) or be flat. The part that slips on the nut is thicker than the box end of a combination wrench in two dimensions. It is deeper than a box end wrench so it has more contact with the nut. It also has thicker walls to prevent the wrench from spreading when twisting/turning it on a nut. Also, it is available in SAE or metric sizes.

So why do I need it

It is a combination of things that make rounding over the flare nut much easier. The nut used on the brake or fuel lines seems on the softer(hardness or grade value) side to begin. Then there is the material that is missing in the middle of the nut where the brake or fuel line goes thru. Also the brake and fuel line nuts are on the smaller size side. These three things seem to allow the nut to round over much easier than a standard bolt or nut. If there is going to be a chance that the nut will be rounded over its always more likely on the fuel/brake line nuts.

What I use

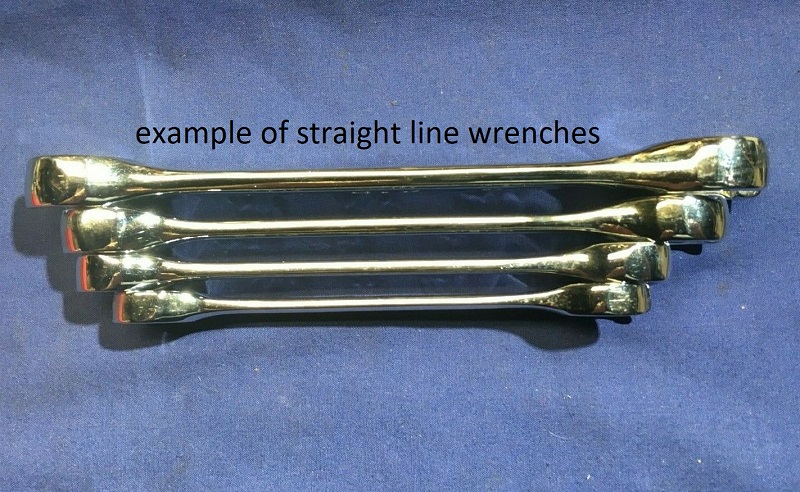

I like the straight version of these wrenches. Without a small angle(called an offset), the nut is not subjected to an angular twisting force. The tradeoff is that a straight wrench needs slightly more room to turn the nut over an angled or offset wrench. Also, I like a six-point version it just has more contact with the nut walls and less chance of rounding over at the corners of the nut. The six-sided versions will need more room for placement on the nut over a twelve-point version.

How I use it

Even though I use a line wrench I always approach a job as if the line nut is going to round over or try to gall as it comes out of its tightened position. So that means that I need to make sure that my line wrench is fully seated on the nut and that prior to removing the nut it has had a liberal amount of penetrating lubricant applied to it. I apply a small amount of twisting force to the wrench and try to move it in small increments(forward about an 8th of a turn, then reverse that 1/8 of a turn, then forward 1/4 and so on) until it is obvious that the threads are not galled or that it will not snap in two as it is loosened.

If you are considering working on your vehicle and its fuel or brake systems I highly recommend the line wrench. It will simplify your life. In the long run, you will find that there will be fewer instances of rounding over line nuts when using a line wrench.

(Image by Charles Risen from Pixabay.com)

(Image by Charles Risen from Pixabay.com)